Artwork/Decoration

Understanding “The our terms of the trade” for the many decorations methods to brand buy customised promotional products with a custom logo can sometimes be exhausting. If you’re not sure what process best suits you here’s a quick insight to all those ways we can decorate promo products using your logo. If your still needing other ideas please call us we have lots of different branding options for the promotional product that you are seeking.

We have invested thousands of dollars into the latest print, engraving and embroidery technologies available for the best quality custom branding on the forever expanding promotional products range.

To create your logo on your preferred items, you will be asked to supply vector artwork ai. (adobe illustrator), Eps. (Photoshop) or a logo designed in other programs alike. Hi- res PDF artwork files, at least 300 dpi in resolution can also be used in some circumstances. If you only have a Jpeg of your artwork that’s okay, just call us to redraw your logo, redrawing artworks from $25+ GST when placing an order.

You will find one or multiple of the branding options mentioned on the product page within the pricing tab or other branding options available for the particular item within description details. These are different methods that can be applied to your elected item. Depending on your product selected, quantity required and lead-time desired, customised branding of your logo can be applied in the following ways to your products selected;

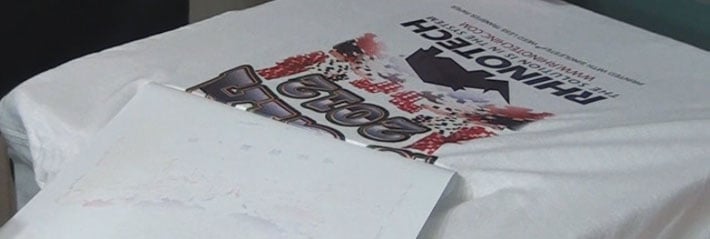

Direct to Garment Printing (DGT)

One of the newest technologies of printing on the market is direct to garment or DTG printing. Used on cotton clothing only you can explore your full colour printing options with this branding process, great for logos with multiple colours, gradient tones or fading effects, print on any fabric colour. This style of print is computer printed and priced on the size of the design, and the amount the of ink the logo uses. Ideal for retail garments and band shirts this style of printing is a trendy way when using logos with full colour imagery. It is not ideal for very high volume orders because it tends to be more costly then the traditional screen printing method in comparison, and may produce very small variations from garment to garment.

A once off $75 Set up fee + GST / Per position applies to this method of decoration.

Direct Digital Printing

You will find a few terms of digital or full colour printing methods splashed around the website, direct digital print is form of printing that gives us the ability to print the some of the most trickiest products in full colour, the print is directly printed on to the product, not a label, not an epoxy domed print. Products such as pens, usb’s and corporate gifts can be printed using a digital logo design without losing the gradient effects or photo like designs used in so many logos used today.

Direct to product digital printing involves the transfer of ink directly from the print heads of an inkjet machine to the product and can be used to produce both spot colour and full colour branding on flat or slightly curved surfaces.

Advantages

Ideal for printing dark coloured products as a layer of white ink can be printed under the artwork.

Can print variable data including individual names.

Only one set up charge is required irrespective of the number of print colours.

Instant drying so products can be shipped immediately.

Offers larger print areas on many products and can print very close to the edge of flat products.

Limitations

Only approximate PMS colours can be reproduced.

Some colours cannot be reproduced including metallic silver and gold.

The size of branding areas is limited on curved surfaces.

Larger print areas tend to be more expensive.

Artwork Requirements

Artwork can be supplied in either vector or bitmap format.

A 3mm bleed should be added to the artwork if it bleeds off the product.

A once off $75 Set up fee + GST / Per Position applies to this method of decoration.

4 Colour Process Printing (CMYK)

The 4 colour process print / 4CP or using the CMYK print method is made up by 4 colours magenta, cyan, yellow and black. This is generally a print method used for stationery or paper products that have a flat surface, used for items like; notepads, presentation folders, mouse mats and signage.

In other cases t-shirts can also be printed using the 4CP print, white background or base colour may suggested to achieve print vibrancy in artwork that includes lots of white or when printing dark coloured garments, the tee colour may show through the image being printed without a base colour applied. This style of print is one of the oldest ways printers have been able to reproduce close to photographic designs until DTG printing.

Here’s where things can be tricky or confusing (4x $75 = $300+ GST) / Per position applies to the screen printed version of the 4 colour printing / 4CP method of decoration, any only 1x setup fee / per product applies for the CMYK printed paper or similar stationery items. While these ways for printing are similar in name, the printing application is very different and far from similar.

Sublimation

Sublimation printing or otherwise known as photo printing an inexpensive branding method used for many items with logos or designs consisting of photographs, gradients and tonal logos.

Always in high demand the stubby cooler or coldie holder is commonly printed using the sublimation branding method.

Other ways to use sublimation printing; pencil cases, signage, clothing, flags, coffee mugs, bar runners, table clothes and more.

Sublimation print is used for branding products that have a special coating on them or fabrics suitable for the sublimation process. A transfer is produced by printing sublimation ink onto transfer paper and then heat pressing it onto the product.

Advantages

Sublimation ink is actually a dye so there is no ink build-up on the finished print and it looks like part of the product.

Ideal for producing vivid full colour images as well as spot colour branding.

Can print variable data including individual names.

Only one set up charge is required irrespective of the number of print colours.

The branding can bleed off some products.

Limitations

Can only be used for suitable products with white surfaces.

Only approximate PMS colours can be reproduced.

Some colours cannot be reproduced including metallic silver and gold.

When printing large images some minor imperfections may appear in the print or around the edges of it. These are unavoidable.

Artwork Requirements

Artwork can be supplied in either vector or bitmap format.

A 3mm bleed should be added to the artwork if it bleeds off the product.

A once off $75 Set up fee + GST applies to this method of decoration.

Screen Printing

This is the most traditional form of printing. It produces the highest quality results. You can use this technique to print onto almost any type of garment the silk screen print has been used for centuries printed on some of the most finest printed flat surfaced substrate. Designs which use gradients, shades and complex colours – such as images or photos are not recommended for screen printing.

Screen printing is achieved by forcing ink through a fine mesh screen with a squeegee onto the product and is ideal for branding flat or cylindrical objects.

Advantages

Large print areas are possible on both flat and cylindrical products.

Most PMS matches are possible on white or light coloured products or with an added white base colour used as a primer to achieve a more true PMS.

Ideal for large solid areas of colour.

Most screen print inks are quick drying and can be shipped immediately after printing.

Metallic gold and silver inks are available.

Limitations

Halftones and very fine lines are not recommended.

Close PMS matches are more difficult on darker products and will only be approximate.

Unable to print variable data.

A set up charge is required for each colour to be printed.

Artwork Requirements

Artwork should be supplied in vector format.

Stick to simple for best quality results when screen printing. Handy fact: Always wash in cold water for longer lasting prints.

$75 Set up fee + GST per colour / Per position applies to this method of decoration.

Pad Printing

Used for smaller items, this print is only restricted by the products surfaces and printable areas, each individual’s design needs to be resized at a legible type sizes, that both the customer is happy with and approves.

Pad printing uses a silicone pad to transfer an image to a product from a laser etched printing plate. It is one of the most popular and affordable ways of branding promotional products due to its ability to reproduce images on uneven or curved products and print multiple colours in a single pass.

Advantages

Ideal for printing on curved or uneven products.

Close PMS matches are possible on white or light coloured products.

Metallic gold and silver is available.

Limitations

Halftones cannot be consistently reproduced.

The size of branding areas is limited on curved surfaces.

Unable to print variable data.

Close PMS matches are more difficult on darker products and will only be approximate.

Minor print distortion may occur on uneven or curved surfaces.

Pad print inks require a curing period before the product can be shipped.

A set up charge is required for each colour to be printed.

Artwork Requirements

Artwork should be supplied in vector format.

$75 Set up fee + GST per colour / Per position applies to this method of decoration.

Embroidery

This is ideal for uniforms and bags, embroidery is a craft that has been used throughout century’s. With hundreds of colours available the sheen or metallic sparkle the of the thread has a quality finish like no other decoration method.

Standard flat stitch embroider your logo or use the 3D Embroidery commonly used on the baseball and basketball caps official team merchandise. This is raised logo effect, essentially pipping that is sewn over looks great for single letters and simple icons.

A once off $75 Set up fee + GST applies to this method of decoration per logo.

Heat Transfer

This is a high quality substrate which is printed with a wide format digital printer using eco-solvent inks to produce your logo or image as a Digitally Printed Transfer. Since the transfers are digitally printed using a full colour process, the number of colours in a design does not effect the price making this method of branding ideal for small quantity orders.

Artwork can contain special effects, shading, photo images, and be cut to pretty much any required shape. Great for individual names and numbers and sporting team merchandise. Pricing for transfer printing is supplied based on the size of the transfer itself.

Digital transfers are used for branding fabrics and are printed on transfer paper using a digital printing machine then heat pressed onto the product.

Advantages

Cost effective method for producing spot colour or full colour transfers.

Crisp, clear artwork reproduction is possible even on textured fabrics.

Has a matt finish and will not crack or fade under normal circumstances.

Can print variable data including individual names.

Only one set up charge is required irrespective of the number of print colours.

Limitations

Only approximate PMS colours can be reproduced.

Some colours cannot be reproduced including metallic silver and gold.

A thin, clear line of glue can sometimes be seen around the edges of the image.

More expensive than offset transfers.

Artwork Requirements

Artwork can be supplied in either vector or bitmap format.

Set up fee is priced within the size and quantity for this method of decoration.

Embossing/De-bossing

is a form of stamping your design. A block or mould is created and then can be blind stamped ( no colour), gold or silver foil stamped into substrates like leather or imitation leather products, other examples for uses of embossing or de-dossing can be used for our silicone range, charity wristbands, rings and more.

Pricing your preferred method is easy. Simply request the size of branding, The large size is only used in super large branding required, the most popular is the small block and medium sizes.

A set up fee in 3 most common sizes; small $180+ GST, medium $220+ GST and large $270+GST applies to this method of decoration.

Label

When were referring to a label this is essentially a sticker, a digitally printer label with adhesive backing printed and then applied to certain products; bottles, lotions or packaging – mainly used on our confectionery range labels can be die cut to a shape when requested.

Digital adhesive labels are used to brand products that cannot be branded with any other method. They are printed with a digital printing press and applied to the product.

Advantages

Ideal for producing vivid full colour images as well as spot colour branding.

Can print variable data including individual names.

Only one set up charge is required irrespective of the number of print colours.

The branding can bleed off the edges of the label.

Limitations

Only approximate PMS colours can be reproduced.

Metallic gold and silver colours are not available.

Artwork Requirements

Artwork can be supplied in either vector or bitmap format.

A 3mm bleed should be added to the artwork if it bleeds off the product

A once off $75 Set up fee + GST applies to this method of decoration.

Laser Engraving

This is a branding method produced by machine, used on metal products a logo is etched into the surface of the metal resulting with a forever lasting message. Different metals will render a different finishes depending on the metal of the product engraved.

For example a silver pen that actually contains a brass barrel will expose a champagne or honey gold etching, a coloured aluminium pen on the other hand will expose a white or silver etched logo. If you do have a specific finish in mind please talk to us about the product you would like to purchase.

Laser engraving produces a permanent natural finish using a laser to mark the product. Different materials produce different effects when engraved so to avoid uncertainty pre-production samples are recommended.

Advantages

Higher perceived value than other forms of branding.

The branding becomes part of the surface and is permanent.

Gives a similar finish to etching on glassware at a much lower cost.

Can mark curved or uneven products.

Can produce variable data including individual names.

The product can be shipped as soon as marking is finished

Limitations

The size of branding areas is limited on curved surfaces.

Fine detail can be lost on smaller products like pens.

Artwork Requirements

The artwork should be supplied in vector format.

A $75 Set up fee + GST per position applies to this method of decoration

Epoxy Dome / Resin Coated Finish

Resin coated finish is produced by printing the artwork onto a vinyl material with strong adhesive on the reverse. The branded area is coated with a crystal clear resin which is allowed to dry. Once dry, the finished decal is applied to the product and the adhesive forms a permanent bond.

Advantages

Ideal for producing vivid full colour images as well as spot colour branding.

Produces a stunning 3D effect that elevates the perceived value of a product.

Can print variable data including individual names.

Only one set up charge is required irrespective of the number of print colours.

Branding can bleed off the resin coated area.

Limitations

Only approximate PMS colours can be reproduced.

The resin requires a one day curing period before the product can be shipped.

Metallic gold and silver colours are not available.

Larger print areas tend to be more expensive.

Artwork Requirements

Artwork can be supplied in either vector or bitmap format.

A 3mm bleed should be added to the artwork if it bleeds off the product.

A once off $75 Set up fee + GST position applies to this method of decoration.